Finally, An Accurate Digital Speedometer

When You're Tired Of Doing The Math

The Yellow Box

Those of you with analog speedometers don't need to read this, it won't do you any good and you'll just want to gloat anyway because your speedo's are pretty darned accurate already. Gloating is bad for you.Those of you with the digital gauge package that comes with the Fuel Injection on Vulcan Classics, Nomads and Drifters (except 2000 Nomad) are painfully aware your speed readings are way off. How far off? Try ten percent! That not only means the speed reading is inaccurate but you're piling up 10% more miles in that little odometer window than you're actually traveling. That's 10 extra miles every hundred, 100 extra miles every thousand...shoot, that's a thousand extra miles showing on the bike every ten thousand indicated! Now we're talking serious error that's going to cost you money!

You may be thinking Kawasaki could (should) have gotten this right in the first place but the optimistic speedo seems to be a character flaw with almost all metric motorcycles, especially those made in the orient. Vulcans read high, sportbikes read high even the luxo Goldwing has a healthy error built in. Don't go screaming to your dealer demanding accuracy, the Federal Government (yours) allows up to a 15% error, plus or minus when it comes to speed readings.

Now there is a wonderful fix if, like I was, you're tired of constantly doing the math. "I want to do 70 so I have to run the speed reading up to 77", or "I'm in a 40 mph zone which means I can really do an indicated 44".

The "Yellow Box" very efficiently recalibrates the signal being sent from the speed sensor to the instrument. How does it work? You can check the website for details about algorithms and such. The bottom line is..it works and it's very simple to install. (Gadget Note: The site hasn't been updated in some time, you might want to contact them to verify that they're still selling.)

Addition: There's a new kid on the block called the "Speedo-Healer". It's the same concept but offers a "plug and play" interface so you don't have to cut or even solder any wires. The U.S. distributor's web page for the product is here and the manufacturers page (in Hungary) with more complete explanations is here. If you happen to install this product I'd appreciate feedback so it can be posted on this page.

Back to the Yellow Box Install on a Vulcan.

Tools You'll Need

- 10 mm socket or wrench to remove both shift pedals

- 5 mm Allen wrench to remove the left side engine cover (4 bolts)

- Circlip remover or small screwdriver to remove left floorboard circlips

- Wire cutter and/or stripper

- Multimeter or 12v test light

- Soldering iron

- Electrical Tape

Tools that help

- Whiteout (or marker) to mark position of shift levers so you don't have to play with them when re-installing

- Electric Drill if you put the box where I installed mine

Here's How

(thumbnails are provided for the bandwidth challenged. Click on them for larger photos)

It will help a little if you have a lift for your bike. It certainly isn't necessary, but allows you to sit comfortably on something besides the garage floor while working.

- Remove the left floorboard. This might be the hardest part of the job because those darned circlips can be stubborn (I don't have the proper pliers so use a couple of screwdrivers to push the things off the pin)

- Remove both shift levers. You might want to mark the lever positions to make re-assembly simpler

- Remove the left side cover (four 5 mm cap screws)

- Locate the speed sensor (finger is pointing to it in this photo). Note the wires exiting the actual sensor are brown but after the connector they are black or light green. The latter are the wires I'll be referring to through this instruction. The photo shows the three wires already unwrapped from their electrical tape and separated, ready to cut or splice. The wire code is:

- Black w yellow stripe=ground

- Light green w red stripe=speed signal

- Light green w black stripe=12v positive

- Please double check this in case something changed with your bike. Using your multimeter or test light unplug the sensor connector and make sure the black wire with yellow stripe is indeed ground by turning on the key and grounding the wire through your light or instrument. Nothing will happen. Now, with the key still on check the light green wire with black stripe. You should get a full 12 volts from this connection. The third wire, light green with red stripe 'might' give you some voltage reading but it will be something closer to 6 volts. If this all checks out, continue. If something is reversed then make a note of it and as we go through the process make the necessary changes for your bike. By the way, the Kawasaki manual shows all FI bikes from 2001-2004 with the exact same wiring harness and color coding so don't worry about this...just double check everything ok?

- You will only be cutting a single wire. It is the light green with red stripe wire that sends the speed signal from the sensor to the instrument. You can (should) just peel back the insulation on the black wire and the light green with black stripe wire. Note you can use those clamshell clamps to make your splices but they are never recommended on motorcycles. They vibrate and have been known to actually cut wires eventually. Don't actually attach any wires yet.

- It's time to figure out where you'll be stashing the Yellow Box. As it happens (even on California models) there is plenty of room under the left cover. Note mine is a California bike so has the charcoal canister under the cover and that's what you see behind the yellow box. I drilled a 3/8" hole through the backplate and ran the yellow box wiring harness out through that hole. Don't worry about sealing it up just yet, we'll do that later.

- Now you can measure the length you'll need for the harness wires. Allow a little extra 'just in case'. Cut off the excess wire and save it someplace for a day you need a foot of wire for another project.

- Time to solder (or clamp if you really must but it isn't recommended) Please refer to the instructions that come with the Yellow Box. The following is the color code at this writing but you never know when a manufacturer will change harness colors so don't consider this any sort of gospel. "at this writing" you will solder (or attach) the RED wire from the Yellow Box to your previously identified 12 volt power wire (light green w black stripe). Per the earlier instructions you have not cut this wire but only stripped back a bit of insulation so you can solder the Yellow Box wire to it. Now do the same with the BLACK wire from the Yellow Box, attaching it to the previously identified ground wire (black w yellow stripe). Once those are soldered it's time to cut the signal wire. Deep breath and.....snip! The instructions will tell you to remove 3/4 of an inch of this wire for a nice smooth harness when you're finished. For this application, forget it. There just isn't wire to spare. Solder the WHITE wire from the Yellow Box to the sensor side of the signal wire. Solder the GREEN wire from the Yellow Box to the speedometer side of the signal wire. Don't tidy things up just yet. It's time for a test!

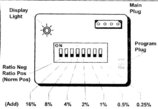

- Per the instructions that come with the Yellow Box set the dip switches to the following settings: (1 is on, 0 is off) 0 1 1 1 1 1 0 0 turn on the ignition and turn your rear wheel. This is easy if it's on a lift, you can walk the bike back and forth a bit if it's on the ground. The red light will blink as the sensor sends its signal. The faster you move the faster the blink. If that's happening you're golden on the input connection. Turn the ignition off.

- Now set the dip switches to 0 1 1 1 1 1 0 1. Turn on the ignition and look at your speedometer. It will be reading just shy of 10 miles per hour. The Yellow Box is sending a steady signal to the instrument. If you can wiggle the wiring and there is no fluctuation in the speedometer needle your output wiring is terrific. Turn off the key.

- Tidy up your wiring by wrapping everything in electrical tape. If you're an over the top neatnick like someone I know you can slide some 1" plastic wire sheathing over the top of everything and give the entire harness a finished look.

- With everything back together you're going to forget the Yellow Box is even mounted on the bike. It'll take awhile to stop doing the math though.

- It's calibration time. If you have a GPS or know someone who does this is a piece o' the proverbial cake. If not then you have a little math to do. The Yellow Box instructions detail all this but I'll make it easy for you. Set the dip switches for 10 percent. ( 0 0 1 0 1 0 0 0 ) If your bike is off by the same amount as mine this figure will give you a 1 mph error at 25 mph (speedo reads 24 at a true 25) but by the time you reach 40 the speedo and GPS are right together up to 85 (the highest I've tried it so far). If you don't have a GPS available you can use highway mileage markers or a trusted friend in a car (with a known accurate speedometer) sending speed signals by hand or talking to you on a radio.

- When the Yellow Box is calibrated and you're pretty sure you won't be fiddling with it anymore, grab a hot glue gun or tube of Silicone glue and seal up the hole you drilled for the wire to pass through the side cover back plate. To help keep dirt out of the switches you can use either of those things to seal the switches too. Just lay a bead right over the top of the dip switches (both peel off if you need to make changes later). Put the side cover back on, go for a ride.

Thanks much to Roman Black and Company for creating a product that, once and for all, through tire size changes, (sprocket changes for bikes that can) and even changes from bike to bike (you can take the Yellow Box with you to your next bike) those who own one never again have to wonder "how fast am I 'really' going?".